DESCRIPTION AND OPERATION

In certain emergency conditions the typical aircraft power generation system already described may not meet all of the airworthiness authority requirements and additional sources of power generation may need to be fitted to the aircraft.

The aircraft battery offers a short term power storage capability, typically up to 30 minutes. However for longer periods of operation the battery is insufficient. The operation of twin-engine passenger aircraft on extended twin operations (ETOPS) flights now mean that the aircraft has to be able to operate on one engine whilst up to 180 minutes from an alternative or diversion airfield.

The two standard methods of providing backup power on civil transport aircraft are:

Ram air turbine (RAT),

Backup converters.

1. RAM AIR TURBINE:

The ram air turbine or RAT is deployed when most of the conventional power generation system has failed or is unavailable for some reason.

The RAT is intended to furnish the crew with sufficient power to fly the aircraft while attempting to restore the primary generators or carry out a diversion to the nearest airfield. It is not intended to provide significant amounts of power for a lengthy period.

The RAT is a turbine, normally stowed in the aircraft ventral section that is extended either automatically or manually when the emergency commences. The passage of air over the turbine is used to power a small emergency generator of limited capacity, usually enough to power the crew's essential flight instruments and a few other critical services.

The RAT also powers a small hydraulic power generator for similar hydraulic system emergency power provision. Once deployed then the RAT remains extended for the duration of the flight and cannot be removed without maintenance action on the ground.

RATs are common in military aircraft which must be capable of surviving sudden and complete loss of power.

Many modern types of commercial airliners are equipped with RATs. In the 1960s the Vickers VC10 was one of the first types of airliner equipped with a RAT.

The Airbus A380 has the largest RAT propeller in the world at 1.63 m in diameter, but around 80 cm is more common. A typical large RAT on a commercial aircraft can be capable of producing, depending on the generator, from 5 to 70 kW.

Smaller, low airspeed models may generate as little as 400 watts.

2. BACKUP CONVERTERS:

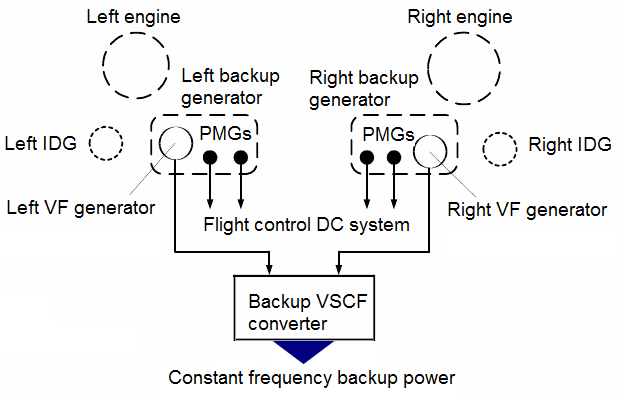

The requirements for ETOPS have led to the need for an additional method of backup power supply, short of deploying the RAT which should occur in only the direst emergency. The use of backup converters satisfies this requirement. Backup generators are driven by the engine. The backup generators are frequency-wild and therefore experience significant frequency variation as engine speed varies. The frequency-wild supply is fed into a backup converter which, using one method, first converts the AC power to DC by means of rectification.

The converter then synthesizes 3-phase 115 V 400 Hz AC power by means of sophisticated solid state power switching techniques.

2.1. Boeing B767 example:

The outcome is an alternative means of AC power generation which may power some of the aircraft AC busbars; we have seen the 115 V AC transfer buses in the case of the Boeing 767.

In this way substantial portions of the aircraft electrical system may remain powered even though some of the more sizable loads such as the galleys and non-essential loads may need to be shed.

Terminology:

Permanent Magnet Generator: PMG,

Variable Frequency generator: VF generator,

Integrated Drive Generator : IDG,

Variable Speed Constant Frequency: VSCF.

2.2. Airbus A340 example:

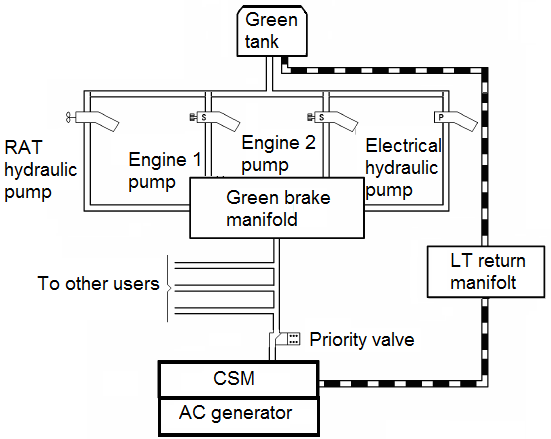

The AC emergency generation which consists of the Hydraulic Electrical Generating System (HEGS) enables to restore part of the distribution network in case of emergency configuration (loss of the two main busbars: AC 1 and AC 2).

The HEGS is composed of the following items:

the hydraulic Constant Speed Motor (CSM),

the AC generator,

the Generator Control Unit (GCU).

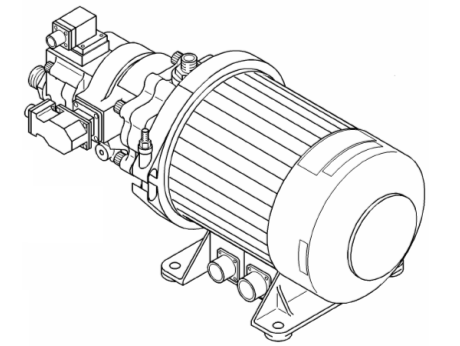

The CSM and AC generator form an assembly called the Constant Speed Motor/Generator (CSM/G) 8XE.

In case of loss of the two main busbars the CSM is supplied by the green hydraulic circuit which is powered:

either by the green hydraulic engine driven pump(s) (one pump driven by engine and/or the other by engine 2) if one engine at least is operative,

or by the Ram Air Turbine (RAT) pump in case of loss of both engines.

In case of loss of the AC main busbars, the CSM supplied by the hydraulic fluid drives the AC generator. The AC generator provides the AC power supply (115 VAC/400 Hz, 3 phases).

It supplies:

the AC ESS buses through the EMER GLC (2XE),

the DC ESS buses (4PP, 8PP) through the ESS TR.

The two main batteries supply the DC ESS BUS (4PP) and, via the static inverter, the AC ESS BUS (9XP) during the transfer to emergency generator operation after the loss of the main busbars.

The CSM/G GCU is supplied by two independent power supply sources:

during CSM/G start phase (12 seconds) by the BAT2,

by the PMG of the CSM/G when the BAT2 supply is isolated.