BEARING LIFE

Fatigue is a type of failure of a material, occurring under alternating loads. Most of the failures of machine details are caused by fatigue.

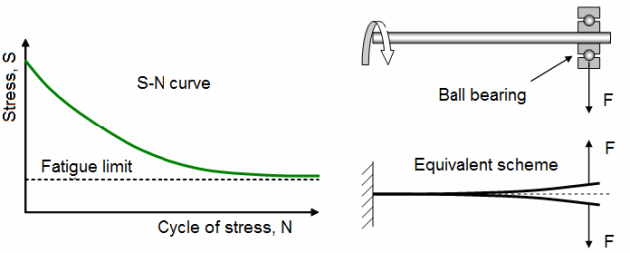

Fatigue life is the number of cycling stresses, causing failure of the material.

Frequency of these stresses is not important.

Fatigue limit is the maximum value of repeatedly applied stress that the material can withstand after an infinite number of cycles.

Fatigue strength at N cycles is the load, producing the material fracture after N cycling applications of the load.

Fatigue limit of a material is much lower, than its ultimate tensile strength.

The rotating specimen in form of a cantilever is driven by an electric motor.

The specimen is loaded by the force F, applied to the ball bearing, mounted on the end of the specimen.

Since the force direction does not change, the direction of the stress applied to the specimen will be reversed each 180º of the shaft rotation.

The tests results are presented in form of S-N curve (stress vs. number of cycles):

Fatigue fracture is characterized by presence of two different types of the surface:

One part is smooth and discolored with ripple-like marks, indicating slow crack growth from the center of the crack formation. Another part of the surface has coarse crystalline appearance resulted from the final catastrophic crack propagation.

The following factors affect fatigue fracture:

Surface factor:

Fatigue cracks form and initiate on the specimen surface therefore hardened and smooth surface (without stress concentrations, notch, flaw) will increase the fatigue limit.

Compressive stress:

Compressive stresses, produced in the specimen surface by shot peening, cold work or heat treatment result in considerable increase of fatigue limit.

Micro-structure defects:

Non-metallic inclusions and other micro-defects may initiate formation of fatigue cracks.

Environmental factor:

Fatigue in the presence of corrosive environment (Corrosion fatigue) occurs at lower cycling stresses and after lower number of cycles.